INTEGRATED SOLUTION

KPPP

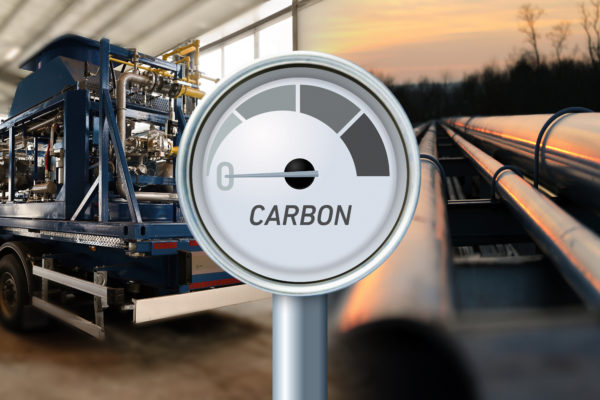

The KPPP – recompression unit for gas pipeline evacuation is a fully integrated system mounted on a heavy-duty steel skid and fixed to a semi-trailer.

It represents a state-of-the-art solution for natural gas handling, featuring a plug-and-play design and an advanced gas recovery system that enhances operational efficiency.

New standard for green industry practices

Minimizing gas loss

Rapid integration ensures minimal downtime and minimizes gas loss during maintenance, repairs, or construction.

Economic savings

Economic savings are achieved through lower operating costs and optimized gas handling.

Input pressure of 2-100 bar

A pressure range of 2-100 bars ensures adaptation to various natural gas transport conditions and ensures reliability and efficiency in operation.

Mobility

Its ability to adapt to various working conditions and access remote locations stands out.

Output pressure of up to 60 bar

Controlled and efficient elevation of gas pressure to ensure adequate distribution and transport through pipelines and the transportation network.

No external power sources needed

No external power sources are required for operation, providing additional flexibility and autonomy.

Environmental protection

The system reduces carbon emissions by preventing the release of natural gas into the atmosphere.

Main components:

- Flexible inlet line and outlet line

- Compressor with horizontal cylinders

- Natural gas AC generator

- Pressure reducing regulator

- Gas flow meter

Main features:

- Suction pressure: 2 – 3 bar(g)

- Inlet pressure: 2-100 bar(g)

- Max discharge pressure: 60 bar(g)

- Max capacity: 2080 Sm3/h

- Gas engine power: 250 kW

- Total weight: approx. 29 t

- Dimensions: 17,50 m x 2,45 m x 3,95 m

Advantages:

- Reduced carbon footprint and methane emissions

- Environmental protection from harmful pollutants

- Mobility to reach even inaccessible locations

- Avoid gas losses during maintenance, repairs, or construction

- Economic benefits through lower operational costs and optimized gas handling

- No external power sources are required

Mobile integrated solution

Hrvatski

Hrvatski