One of the most critical elements for gas companies is pipeline evacuation. As essential industries to the world economy, these companies face unique challenges in managing their production, transportation, and storage facilities.

Pipeline evacuation refers to safely shutting down and emptying pipelines of potentially hazardous or harmful materials.

In this blog post, we delve into what pipeline evacuation entails, its significance, and the challenges it presents.

What is pipeline evacuation?

Pipeline evacuation of natural gas (gas recompression) is extracting gas from a gas pipeline or another enclosed volume at high pressure and reinjecting it into the gas pipeline or an adjacent part of the gas network using a mobile recompression unit.

This practice is applied during maintenance, servicing, hydrostatic testing, repairing, or construction work on gas pipelines, where natural gas is evacuated/pumped from a specific network section for safety or to facilitate the work.

The main goals of pipeline evacuation include minimizing the loss of natural gas, reducing the environmental impact, and achieving financial savings.

In general, the compressor can be driven in various ways. At Macel Plin, we move it through the gas unit. Natural gas is pumped from the high-pressure gas pipeline and re-pumped into the adjacent part of the gas network through pressure regulation and recompression procedures.

The section that needs to be emptied is pre-pumped (emptied), depending on the user’s requirement for the desired emptying pressure.

Benefits of gas recompression

Gas recompression has traditionally been a critical process in various industries, requiring careful consideration of time, cost, and environmental impact. The introduction of mobile recompression units emerges as a response to the industry’s evolving demands, providing a dynamic solution that aligns with the need for flexibility and efficiency.

Energy efficiency

The primary benefit of gas recompression is the enhancement of energy efficiency. Industries can achieve a more sustainable and cost-effective operation by recovering and reusing energy from compressed gases.

Reduced environmental impact

Lower energy consumption directly translates to a reduced environmental impact. Gas recompression contributes to the overarching goal of sustainability by minimizing greenhouse gas emissions associated with energy production.

Operational cost savings

As energy costs continue to rise, businesses are constantly seeking ways to optimize their processes and reduce operational expenses. Gas recompression allows for significant cost savings by reusing energy and minimizing the need for additional power sources.

Challenges in pipeline evacuation

Complexity of networks

Gas pipelines often form intricate networks, covering vast distances. Evacuating such expansive systems poses logistical challenges that demand careful planning and coordination.

Communication hurdles

Effective communication is vital during evacuations. Ensuring seamless communication between employees and control centers can be challenging in remote or offshore locations with limited connectivity.

Risk of contamination

Due to the substances flowing through gas pipelines, any spills or leaks during evacuation could pose a significant risk of environmental contamination. It’s imperative to have robust strategies to contain and minimize these potential risks.

Technological advancements in pipeline evacuation

Early detection and monitoring:

Employing advanced monitoring systems is crucial for the early detection of potential issues within a pipeline. Sensors and monitoring devices can identify anomalies such as pressure drops, leaks, or temperature changes, triggering immediate alerts to operators.

Predictive analytics:

Predictive analytics leverage historical data and machine learning algorithms to forecast potential pipeline issues before they escalate. This proactive approach enhances the effectiveness of evacuation plans by allowing for preventive measures.

Drones and robotics:

Drones with sensors and cameras can provide real-time visual data in emergencies. Robotics technology also plays a role in inspecting and maintaining pipelines, ensuring their integrity, and minimizing the risk of incidents.

What is a gas recompression unit?

A recompression unit is a device or system used in various industrial processes to recompress gases to a higher pressure level. This technology is commonly employed in oil and gas, petrochemical plants, and other facilities where compressed gases are integral to production or transportation.

Compressor units play a crucial role in maintaining the pressure and flow of natural gas within pipelines over long distances. While pipeline evacuation primarily focuses on emergency response and safety measures during unforeseen incidents, the operation of compressors is closely tied to continuous and efficient gas flow under normal operating conditions.

The primary purpose of a recompression unit is to increase the pressure of gases that have been partially expanded or depressurized during certain stages of an industrial process. This is typically done to maintain or reach specific pressure levels required for subsequent processing, storage, or transportation. Recompression units play a crucial role in optimizing the efficiency of these processes and minimizing energy losses.

Key features and functions of recompression units include:

- Energy recovery: Recompression units are designed to recover energy from gases that have undergone expansion. The potential energy lost during the expansion process can be reclaimed and utilized elsewhere in the industrial operation by compressing these gases.

- Pressure maintenance: In industries such as natural gas processing or petrochemical production, maintaining consistent pressure levels is essential for ensuring the proper functioning of equipment and meeting specific operational requirements. Recompression units help in achieving and sustaining these pressure levels.

- Process optimization: Recompression units contribute to the overall optimization of industrial processes by allowing for the controlled and precise management of gas pressures. This is particularly important in applications with varying pressure conditions, and maintaining stability is crucial.

- Cost and energy efficiency: Recompression units contribute to cost savings and increased energy efficiency in industrial operations by reusing energy from previously compressed gases. This is especially valuable in the context of sustainable and environmentally conscious practices.

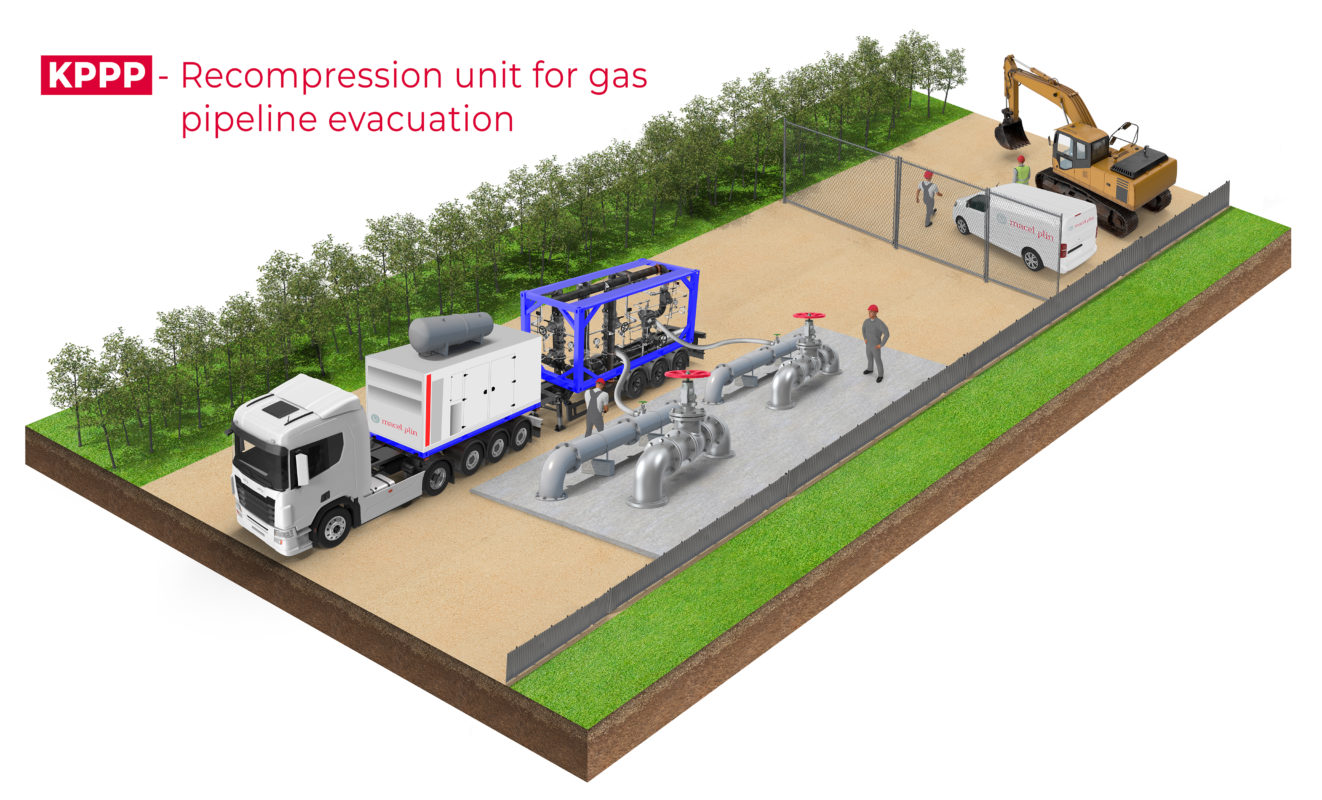

Gas pipeline evacuation by mobile recompression unit

Gas pipeline evacuation using a mobile recompression unit (KPPP) is a complex process that demands careful consideration of various factors to ensure efficiency, safety, and environmental compliance. Here are several important aspects to take into account:

Gas pipeline evacuation using a mobile recompression unit (KPPP) is a complex process that demands careful consideration of various factors to ensure efficiency, safety, and environmental compliance. Here are several important aspects to take into account:

Regular operation and compressor units

Compressor units are installed along natural gas pipelines to maintain the pressure required for the gas to travel over significant distances. These units are strategically placed at intervals to boost the pressure and keep the gas flowing. The compressors help overcome frictional losses and ensure the gas reaches its destination with the necessary force.

Emergencies and pipeline evacuation

The evacuation process becomes crucial in an emergency, such as a leak, rupture, or any other incident compromising the pipeline’s integrity. Evacuation procedures involve shutting down the pipeline, isolating the affected section, and removing personnel from the danger zone. Compressor units may be temporarily shut down or adjusted as part of the emergency response plan.

Pressure management during evacuation

During pipeline evacuation, it is essential to manage the pressure within the pipeline to prevent further incidents or potential damage. The compressor units can play a role in adjusting pressure levels based on the specific requirements of the evacuation plan. This may involve reducing or diverting the flow of gas to minimize the impact of the emergency.

Communication and coordination

Both compressor units and pipeline evacuation procedures require effective communication and coordination. Operators must communicate with each other, emergency responders, and relevant authorities to ensure a smooth and safe response to any situation. Information about compressor status, pipeline conditions, and evacuation plans must be accurately shared among stakeholders.

Technological integration

Modern pipeline management systems often integrate advanced technologies for compressor control and emergency response. Automation, remote monitoring, and predictive analytics can enhance gas transportation’s efficiency while providing early warnings and data for effective evacuation planning.

Takeaway

Pipeline evacuation of natural gas achieves resource conservation, efficient energy transport through gas pipelines, and financial savings.

Reducing gas losses and minimizing the negative environmental impact represents an important step towards a more sustainable use of resources and a reduction in the ecological footprint of gas pipeline systems.

We employ effective cross-compression practices, whether it’s an urgent maintenance situation or a scheduled event between compression stations, pipeline distribution, transmission, or storage. Our team collectively works towards reducing methane emissions and promoting a safer, more sustainable natural gas value chain.

If you’re looking for reliable pipeline evacuation services, request a quote. We commit to ensuring the safety of your operations and preserving valuable resources.

Hrvatski

Hrvatski