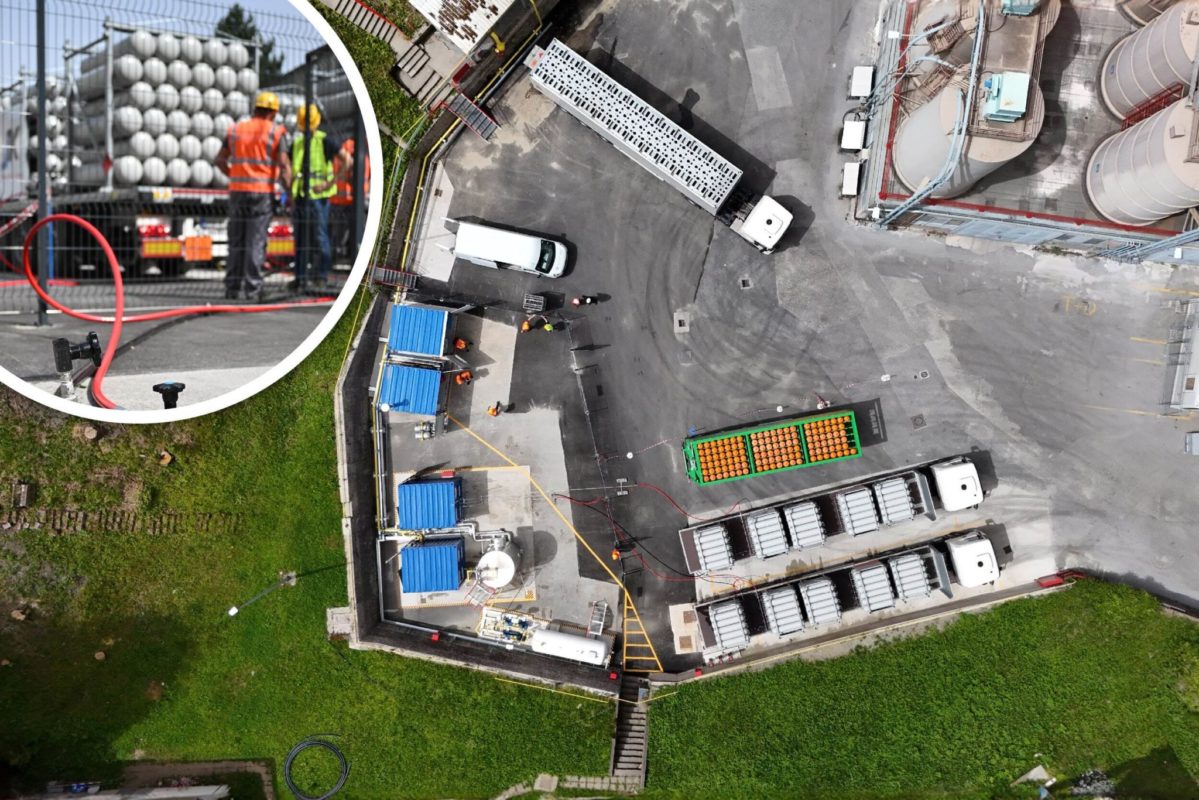

The Vetropack Straža d.d. factory, the only manufacturer of glass packaging in Croatia and part of the Swiss Vetropack Group, successfully addressed the announced interruption of natural gas supply by constructing a modern gas station within its industrial complex. The new station enables the supply of synthetic gas to the factory by blending liquefied petroleum gas (LPG) with air and reducing compressed natural gas and natural gas from compressed natural gas (CNG) storage tanks.

Integrated technological solution GRIZO

The project comprises several key units that make an integrated technological solution:

1. Vaporize and gas blending unit station

The vaporize and gas blending unit station with a capacity of 2,000 m³/h, ensures high efficiency in gas processing. The LPG tank in the station has a volume of 4.85 m³ and provides sufficient space for storing liquefied petroleum gas (LPG).

Equipment for LPG transfer includes pumps equipped with control and shut-off valves, allowing precise control of gas flow. Additionally, the station is equipped with an LPG evaporator that converts liquefied gas into a gaseous state and an LPG blender, ensuring a homogeneous mixture of gas and air for further use.

2. Measuring and regulation station

The 2,000 m³/h capacity compressed natural gas regulation station is designed for efficient transmission and pressure regulation of natural gas. The station is equipped with sophisticated equipment that enables safe and reliable reduction of high gas pressure to the required level for distribution or use.

The capacity of 2,000 m³/h allows the station to process large volumes of gas, ensuring a stable and continuous gas supply. The measuring and reduction station includes advanced safety systems, such as pressure control valves, flow monitoring sensors and gas leak detectors, ensuring maximum safety and efficiency in operation.

The station is a key component of natural gas distribution infrastructure, optimizing supply to various consumers, including industrial users, commercial facilities, and households.

3. Ancillary facilities

The project includes several ancillary facilities that ensure optimal functioning of the system:

Boiler room

The boiler room consists of five modular boilers with a total capacity of 250 kW. The operational mode is set at 80/60°C. Hot water pipelines connect the boiler room to the LPG evaporator and natural gas preheater, ensuring efficient heat transfer within the system.

Air compressor room

The air compressor room is equipped with three frequency-regulated screw compressors, each with a power of 22 kW. In the compressor room, there are also refrigerated dryers, micro filters, and moisture separators, that provide optimal conditions for system operation. A 1,000 m³ capacity compressed air tank is connected to pipelines leading to the blender, ensuring reliable supply of compressed air.

Low-pressure gas pipeline

Thanks to the application of the balloon method, the DN100 low-pressure gas pipeline can be connected to the existing gas pipeline without interrupting gas supply. This method ensures safe and continuous gas supply during pipeline connection works.

Project implementation

Both stations were designed and manufactured at Macel Plin d.o.o. production facilities and successfully integrated at the Vetropack Straža d.d. location site after obtaining building permits. Construction works and connections to the existing gas pipeline were carried out using the ballooning method without interrupting the supply.

Inspections and operational permit

Before the supply suspension, the relevant authorities conducted comprehensive inspections and a technical review, as well as a technical inspection, which resulted in the issuance of an occupancy permit.

“During the suspension, which began on June 18th in the early morning hours and lasted a total of 38 hours, the production process in the company Vetropack Straža d.d. proceeded without any problems. Although the supply disruption was predicted to last 48 hours, the suspension ended 10 hours earlier. During that period, a compressed natural gas (CNG) reduction station was in operation, equipped with 18 multi-element CNG tanks (MEGCs) with a total capacity of 110,000 m³, which ensured a continuous supply of gas”, said Damir Jeličić from Macel Plin d.o.o.

As a safety measure, a mixing and vaporization station was on standby, ready to take over in case of any unforeseen situations, thereby ensuring additional reliability and safety in the gas supply during the suspension period.

Conclusion

The gas supply station has ensured production continuity and energy supply stability, crucial for the successful operation of the factory. Thanks to this station, Vetropack Straža d.d. has relied on a reliable and stable gas source, minimizing the risk of production interruptions due to energy supply disruptions.

Based on the risk reduction policy implementation and backup system strategy during the recent gas supply interruption at the factory, it is clear that preparing the infrastructure for alternative energy supply can significantly reduce business risks.

This project serves as a model of good and successful business practices, which can be an example to other large energy consumers who face high losses during supply interruptions.

Investing in safety measures such as backup systems and alternative energy sources ensures operational continuity and strengthens operational resilience and competitiveness in the market. Therefore, the importance of a proactive approach to managing energy risks, flexibility, and adaptability in business strategy to avoid potential negative consequences of energy supply interruptions should be emphasized.

“The project was carried out with quality and within the agreed deadlines, which met all the envisaged standards and specifications. The main goal of the project – ensuring an alternative supply of energy for the glass factory – has been fully achieved.”

Hrvatski

Hrvatski